As the components are still arriving, we are already preparing to assemble and modify the frame. This frame will serve as the skeleton of the simulator, as everything—from the wheel, seat, and monitors to the PC and other elements—will be mounted to it.

First, we join the lower two parts and secure them with M8 screws. Then comes the modification. We need to drill new holes in the middle section because the original monitor stands are too low. Additional holes must also be drilled directly into the monitor stand to achieve the combined clearance of 17 cm that we need. These holes are then filled with M8 rivet nuts, and we proceed to assemble the middle and top sections.

We also replace the standard static legs with lockable wheels, so the simulator can be moved easily. Six brakes will help keep it securely in place when needed.

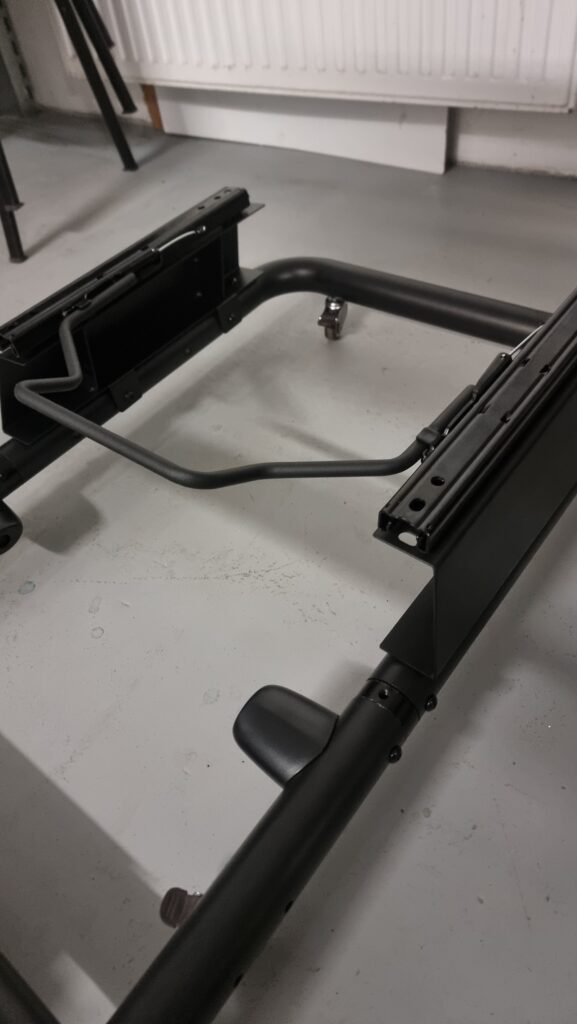

The original seat position is shifted slightly forward, which requires drilling and riveting eight new holes. It’s now ready for the seat riser and seat sliders, allowing for adjustment to the driver’s needs.

Finally, we install a mounting frame for the three monitors, completing the base of our simulator.

Next up is the PC build—which won’t be just a standard build, but an integrated solution within the simulator itself.